Npk compound fertilizer granulation equipment is widely used in npk fertilizer making line. we have both dry type pellet mill and wet type drum pelletizer for your references. What’s more, if you use different granulation methods for your fertilizer granulating, the process are different, too. Meanwhile, as a professional fertilizer facilities manufacturer, we can provide you professional suggestions and fertilizer granulation equipment for your compound npk fertilizer plant. It is realizable for you to get high qualified compound fertilizer granulating machine with attractive price here.

npk compound fertilizer granulation equipment for sale

- Model: SXZGZ-3210(can be customized)

- Power(Kw): 37

- Diameter(mm): 3200

- Length(mm): 10000

- Installation Angle: 2-5°

- Capacity(t/h): 15-30

What’s the functions of npk compound fertilizer granulation equipment?

An npk compound fertilizer granulation equipment is a machine for making the npk materials into fertilizer pellets. The materials for npk fertilizer granulator are powdery usually. If you put the powdery materials into npk granulator machine, the materials will be granulated into specific shapes. You can apply this machine on your npk fertilizer manufacturing process. It is often used after the mixing process. The mixer blends powdery materials evenly and then the granulation machine will turn them into fertilizer granular. Using the npk fertilizer pelletizer, you can get npk fertilizer pellets easily.

What npk fertilizer production technology is employed by an npk granulator?

Generally speaking, there are dry and wet granulation methods for granulating. The compound fertilizer dry granulator uses extrusion force for making powders into pellets. While, if you use the wet granulation equipment for pelletizing, you should add some liquid into the materials when granulating. Because the materials can not become balls naturally and the liquid can improve the adhesive force.

Disc Pelletizer

Rotary Granulator For Sale

Double Roller Granulator

Pan Granulator For Sale

Wet granulation technology

During the wet granulation process, you can add some liquid. Meanwhile, the liquid you use should be volatilizable and nontoxic. For example, ethyl alcohol and isopropanol are suitable for adding. Using these liquid, the finished fertilizer granular will be more convenient for drying. However, if you use water as adhesive, the powder will be separated when it is dried. Thus, it is necessary for using the liquid which includes binders.

wet rotating npk fertilizer granulator for sale

- Model: SXZGZ-1240(can be customized)

- Power(Kw): 5.5

- Diameter(mm): 1200

- Length(mm): 4000

- Installation Angle: 2-5°

- Capacity(t/h): 1-3

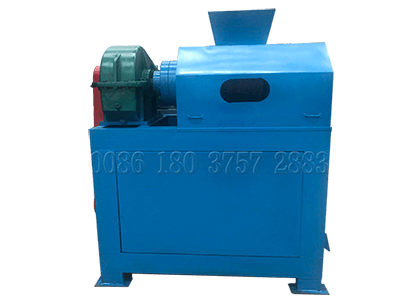

Dry granulation technology

This dry granulation technology is applicable for granulating the materials, which are not suitable for mixing with liquid. It presses the powder into specific shapes. This dry granulation pelletizer is a key equipment in the compound fertilizer production line.

Npk compound fertilizer granulation equipment with different granulation methods

Shunxin fertilizer granulator supplier has both dry type compound fertilizer granulating machines and wet granulation facilities for your npk fertilizer production. They are different in not only the granulation methods, but also production capacities and sizes.

Fertilizer roller compactor facilities for sale

The double roller press machines uses drying-free process. It makes pellets with extrusion force and you don’t need to add any liquid for granulating, you don’t need to dry them after the fertilizer compaction granulation. Especially, roller extrusion pellet mill can manufacture fertilizers at room temperature. Meanwhile, you can choose the shape of finished fertilizer granules according to your preference. We can customize for you.

dry roller extrusion granulator for sale

- Model: SXJZ-1T(can be customized)

- Granule Diameter(mm): 3-10

- Roller Sheet Size(mm): 150×220

- Dimensions(mm): 1450×800×1450

Wet type rotary drum granulation machines for sale

This drum pelletizer is an equipment which adopts wet granulation technology. When you add water or vapour into the compound fertilizer granulator during the granulation, the base fertilizer will have chemical reaction with them. What’s more, under certain liquid conditions, the materials particles will get squeezed into balls because of the rotating. The rotating granulator machine has high output. It is suitable for your large scale granulated compound npk fertilizer making plant. Beside, our pan tye wet granulation equipment is also an ideal granulator for your NPK fertilizer granules making.

wet type drum pelletizer for sale

- Model: SXZGZ-1870(can be customized)

- Power(Kw): 15

- Diameter(mm): 1800

- Length(mm): 7000

- Installation Angle: 2-5°

- Capacity(t/h): 5-8

What kind of role does the npk granulator machine play in your granulated compound npk fertilizer plant?

The rotary drum npk compound fertilizer granulation machine is a key equipment in the npk fertilizer production line. Then how does it work with other equipment?

- Before the granulation, you should batch your straight fertilizers in a proportion. If you batch them in a proper proportion, the fertilizer will be more fertile.

- The npk granulator machine accepts powdery materials. The crushing machine and blenders are helpful. A fertilizer pulverizer can make the batched materials into fine powders. And then you can use the powder blending machine for mix them evenly.

- After the crushing and mixing, the powdery materials are suitable for granulating. If you use the dry npk fertilizer granulation machine, you can put the powdery materials into the feeding port. Then there will be extrusion force which can press the powders into big tablets. There is a crushing room in the roller granulator, which can crush the tablets into pellets. The shapes of pellets can be customized.

What’s the process after the npk fertilizer granulation?

After the granulation, there are some processes you should do to finish your npk fertilizer production. Using different npk compound fertilizer granulation equipment, the processes are different, too.

- Drying and cooling process. If you use the rotating drum pellet mill for making npk fertilizer pellet, you should equip with a drying machine and a cooler. With these types of equipment, your fertilizer granules will be more convenient for transporting and storing. If you use the dry type npk fertilizer granulating equipment, this process is unnecessary for you.

- Screening process. This process is aimed at selecting the unqualified pellets out. And then you can put the unqualified fertilizer granules into the crushing machine for granulating again. We manufactures different screeners for your sieving requirements.

- Coating process. A coating machine will make your finished fertilizer granular smoother. Meanwhile, this process also improves their physical characteristics.

- Packing process. For saving your time on weigh and bag the fertilizer products, we provide you automatic bagging machines. If you use this machine for your packing, your production efficiency will be higher.

NPK fertilizer granulator equipment for sale

- Model: SXJZ-2T(can be customized)

- Granule Diameter(mm): 3-10

- Roller Sheet Size(mm): 185×300

- Dimensions(mm): 1630×850×1650

How to choose a fair price granulator for your granulated compound npk fertilizer plant?

Operating an npk fertilizer making factory, one of the most important thing you should consider is the cost. Except the cost of plant, the facilities also affects the costs much. Then how to choose a favorable granulation equipment?

Choose a trustworthy fertilizer granulator machine manufacturer

A trustworthy fertilizer equipment supplier will save your costs and time on many things. For example, when you asking some professional questions about the compounds extrusion granulator, a professional supplier will deal with it well. And if you have any troubles during your fertilizer production, a good after-sales service can reduce your production loss. Shunxin fertilizer making equipment manufacturer is professional with manufacturing experience. We have many customers at home and abroad and our products have good reputations. Moreover, our equipment manufacturing engineers are expert with advanced concept.

Choose a suitable granulator for your fertilizer production

The npk compound fertilizer granulation equipment prices are different because of the different sizes, production capacity and configurations. According to your plant scale, fertilizer production capacity, we can recommend you suitable compund fertilizer granulator at favorable price.

NPK fertilizer pan granulator for sale

- Model: SXYZ-1200(can be customized)

- Diameter of Disc(mm): 1200

- Edge Height(mm): 250

- Dimensions(mm): 1200×1470×1700

- Capacity(t/h): 0.3-0.5

Customized NPK fertilizer granulation machine configuration for Turkmenistan

These machines are manufactured for our customer from Turkmenistan: SXYZ-1200 pan granulator and dry type roller extrusion NPK fertilizer pelletizer SXJZ-1T.

This SXYZ-1200 can produce 0.5 ton NPK fertilizer granules per hour. It utilizes centrifugal force for pelletizing. Meanwhile, you can control the size of pelleted NPk fertilizer granules. And the SXJZ-1T fertilizer roller compactor machine can make NPK ferilizer pellets with 1 ton per hour production capacity. These two machines can work together for making granular NPK fertilizers simultaneously.