Wawaafar Rotary waa mashiin ku dhaari kara waxyaabaha ku jira qaabab gaar ah. Waxay ku habboon tahay wax soo saarka cabirka ballaaran ee qabow, Grance kulul iyo bacriminta isku dhafka ah iyo hoos udhaca hoose. Maxaa ka badan, Waa mid ka mid ah tas-hiilaadka muhiimka ah ee loo sameeyo bacriminta xarunta. Waxaad ku qalabeyn kartaa mashiinno kale si aad u sameysid khadka wax soo saarka Bacsiga oo dhammaystiran. Our company provides you complete supporting facilities including batching machines, screeners, blender and so on.

The rotary wet granulator can produce not only compound fertilizers, but also organic fertilizer as the disc pan granulator machines. Dhanka kale, it also uses wet granulation method. If you want to make fertilizer with dry granulation method, we can provide you double roller press granulator for dry granulation. And we also have new organic fertilizer granulator for making pure organic fertilizers if you need.

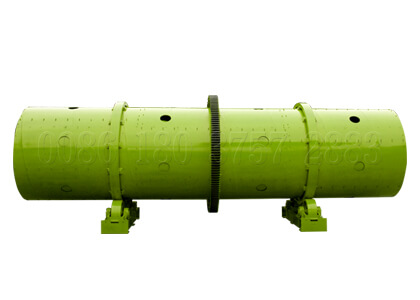

rotary granulator for sale

Nooc: SXZGZ-1240(waa la habeyn karaa)

Awood(Kr): 5.5

Dhexroor(mm): 1200

Dherer(mm): 4000

Xagal rakibaad: 2-5°

Mug(t / h): 1-3

Why choose rotary granulator?

Rotary drum granulator overcomes the defects of disc pelletizer including the low production, low strength of finished granules and so on. Waqti badan, when you are making compound fertilizer by disc pan granulator, it’s difficult for you to add some steam in. Rotary granulator machine realizes this production technology.

Comparing with pan granulator, drum pelletizer is more suitable for large scale production. Its output can reach 30 Ton saacaddii. This can bring more economic efficiency to your fertilizer plant. Dhanka kale, it doesn’t need too much labor force to operate it. If you want to get high output, high economic benefits and low labor force consumption, why not have a try on drum granulator?

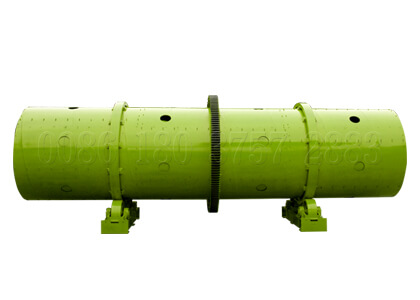

30 ton per hour drum pelletizer for sale

Nooc: SXZGZ-1240(waa la habeyn karaa)

Awood(Kr): 5.5

Dhexroor(mm): 1200

Dherer(mm): 4000

Xagal rakibaad: 2-5°

Mug(t / h): 1-3

How does the rotary granulator work?

This rotating pelletizer granulates pellets by centrifugal force. It rotates the cylinder. Then the powders will get together and become pellets. Ma taqaanaa sida walxahasta oo ay wada shaqeeyaan? Oo sidee baad u sameyn kartaa si wanaagsan u xajista?

Sidee buu qaylada kasta oo granulauraha ka kooban yahay wada shaqaynta?

Suunka iyo jiidista waxaa kaxeeya matoorka ugu weyn. Markaas agabku waxay ku dhex dhici doonaan qadka wadista si loo yareeyo. Qalabka furan ee lagu rakibay wadooyinka wadida waxay la shaqeysaa giraanta waaweyn ee qalabka. Giraanta geeska ayaa lagu hagaajiyaa jirka. Oo leh qaab-dhismeedka gaarka ah ee dhululubada, Alaabada ceyriinka ah waxay ka koobnaan karaan qayb ka mid ah.

Waa maxay hababka ay hababku u shaqeeyaan mashiinka?

Grandariton qoyan Rotary waxay qabataa habka geedka qoyan. Oo leh xaddi yar oo biyo ah ama uumi, Waxaa jiri doona jawaab celin kiimikaad oo ku taal dhululubo. Dulucda wareegga dhululubo ayaa ka dhigi doonta qalabka. And then materials will become pellets under a certain liquid condition.

How can the granulator perform better?

With vapour, gas ammonia, or phosphoric acid or nitrogen solution, phosphorous ammonia slurry, heavy calcium slurry, the materials can be with uniformity and humidity in the rotary drum. Umushay, there will be chemical reactions and heating reactions in the tube. Ugu dhambayntii, the finished fertilizer pellets can be 3mm~4mm.

Drum type fertilizer granulating equipment

Nooc: Sxzgz-3210(waa la habeyn karaa)

Awood(Kr): 37

Dhexroor(mm): 3200

Dherer(mm): 10000

Xagal rakibaad: 2-5°

Mug(t / h): 15-30

What is the fertilizer drum granulation production process?

Utilizing the drum rotating equipment for granulating, do you know the granulation process? Here we can show you the detailed granulation process for making fertilizer granules when you use drum granulator as granulation machine.

- Before the granulation, you should make sure your materials are powdery. It is necessary for you to use powdery fertilizer as materials for drum granulation. If your materials are not fine for granulating, you had better apply a fertilizer crusher for making fine powdery fertilizer materials.

- When you feed fertilizer powders into the granulation equipment, the cylinder will be rotating and rotate the powders to granules. The pelleted fertilizers will be out when it becomes granules. Dhanka kale, if you need, it is also applicable for you to add some vapour for pelletizing better.

- After the granulation, you should dry the granulated fertilizers to make it more convenient for transporting and storing. There are drying and cooling machine for you to process them more efficiently.

Sidoo kale, Shunxan sidoo kale waxay ku siinaysaa xoogaa mashiin kale oo kaaliye ah. Waa Beddelka Adiga oo ku habeeya mashiinno kala duwan iyadoo la raacayo shuruudahaaga. Waqti badan, Waa la heli karaa si loo habeeyo adiga. Oo waxaan sidoo kale kuu qaban karnaa.

Si dhammaystiran 20 tan saacad kasta oo khadka soo-saareyaasha bacriminta ee dabiiciga ah ayaa lagu habeeyay SXZGZ-1240 Mashiinka Mashiinka Duruunka

Soo-saarka bacriminta, Waxaan kugula talineynaa macmiilkayaga noocan bacriminta pellizer sida ku xusan shuruudaha macaamiisheena. Xaruntaan ee wareegga ee wareejinta ee ku wareegsan 20 Ton saacaddii. Way ku caawinaysaa dhirta wax soo saarka ee bacrimiyeyaasha waaweyn. Gaar ahaan, Waxay ku habboon tahay in wax soo saar bacrimi ah oo dabiiciga ah iyo isku dhafan labadaba. Mashiinkaani wuxuu u adeegsadaa tikniyoolajiyadda weyn ee qoyan ee loogu talagalay pellizizing. Haddii qalabkaaga budada ahi yahay mid dabiici ah ama bacrimiyeyaal isku dhacay, Waxay u rogi kartaa ceelka bacriminta si fiican. Dhanka kale, oo lagu qurxiyo qalab kale, sida Mashiinka qalajinta, Mashiinka qaboojinta, shashiis, itc. , pellisiska la dhammeeyay. Waqti badan, Wixii aad ganacsigaagu u weyn ee miiskaaga ganacsiga ee ganacsiga, Waxa kale oo aad u isticmaali kartaa mashiinka xirxiran si aad si hufan u soo qaadato.

Sideen ugu yeelnaa naqshadeeyaha Roweelulator naqshadeynta?

Samaynta bacriminta Pellizer Pelletizer wuxuu si joogto ah oo waara, Waxaan ka shaqaalaynaa qalab tayo sare leh mashiinkan. Maxaa ka badan, Waxaa jira naqshado jilicsan oo jilicsan oo durbaan ah oo kuu ah inaad si sahlan u geyneyso.

Qalab tayo sare leh oo ku saabsan Qeybaha Claller iyo Qeybaha Kaabta Ka Saabsan Mashiinka Xakamaynta

- We employ medium carbon steel plate and U-steel to strengthen the cradle, because it supports the rotating of the whole cylinder body. In consideration of the friction between riding wheel and belt, we use antirot and abrasive materials to prolong its service life.

- The driver adopts high quality U-steel to make sure the machine work stable. Maxaa ka badan, the U-steel has reached the national standard.

High tech wear-resistant materials on gearwheel prolong machines service life

- The large gearwheel is installed on the cylinder body and works with the small gearwheel. They all adopt high tech antiwear materials, which prolong the service life of drum type rotary granulator.

Special materials on cylinder liner make cylinder body work better

- The liner is made of rubber, which makes the materials not easy to stick. And it also have functions on antirot and insulation.

- The cylinder employs special rubber liner and acid-resistant stainless steel liner, which realizes the automatic smashing, the removing of tumor. Ee dib sii dheer, it eliminates the traditional scraper device.

Sidoo kale, to transport conveniently, there are 4 hooks on the carrier roller mounting bracket. This rotary granulator design also provides convenience for loading and unloading.

Dedicatly designed rotary granulator for sale

Nooc: Sxzgz-3210(waa la habeyn karaa)

Awood(Kr): 37

Dhexroor(mm): 3200

Dherer(mm): 10000

Xagal rakibaad: 2-5°

Mug(t / h): 15-30

5 irresistible reasons for you to choose rotary drum granulator machine

- Because of the high quality liner, the rotating granulator has long service life.

- Its granulation rate can reach 70%. Waqti badan, the small pellets are less. Even if there are unqualified pellets, you can granulate them again.

- By improving the materials temperature with the vapour, the pellets will have low moisture contents. Isla mar ahaantaana, it improves the drying efficiency.

- You can make different fertilizers by this machine, including high nitrogen compound fertilizer whose nitrogen content is above 20%, special fertilizers, organic-inorganic fertiliser and so on.

- It can be widely used with varieties of raw materials. You can mix low solubility materials with high solubility according to the formula. Waqti badan, it is applicable to add some organic matter and microelement.

Drum granulator for sale

Nooc: SXZGZ-1870(waa la habeyn karaa)

Awood(Kr): 15

Dhexroor(mm): 1800

Dherer(mm): 7000

Xagal rakibaad: 2-5°

Mug(t / h): 5-8

4 preparation steps to operate your rotary granulation machine safely and efficiently

This drum pelletizer should be installed on the horizontal concrete foundation, fixed with foundation bolt. And the motor body should be vertical to the horizontal.

Check the bolts to make sure whether they are loose or not.

Then you’d better look out whether the host door is fastening or not after your installation.

Dispose the power cord and control switch in accordance with the power of equipment.

Take a no load test after you finish checking. And then you can granulate trustingly. Here are steps for no load test:

- Run the drum rotary in ballast for 8 hours. It shows the machine works normally if the bearing temperature rises steadily. And the temperature should be no more than 50°C if you stop the machine.

- Focus on the noise of gearwheel, making sure it is normal.

Rotating drum fertilizer pellet making equipment for sale

Nooc: SXZGZ-1870(waa la habeyn karaa)

Awood(Kr): 15

Dhexroor(mm): 1800

Dherer(mm): 7000

Xagal rakibaad: 2-5°

Mug(t / h): 5-8

How to maintain the rotary granulator to make it work better?

Waxaad si fiican u isticmaali lahayd saliida saliidda sare ee saliidaha, Sababtoo ah waxay door muhiim ah ka cayaartaa mashiinnada’ orgieya. Waxay saameyn ku yeelanaysaa nolosha adeegga mashiinka durbaanka. Waa inaad u isticmaashaa saliidda saliidda qaybaha soo socda:

- Qaadashada wareejinta

- Duubid

- Dhammaan dharka

- Dhacdo firfircoon, Diyaar garow

- Hubi dhibcaha badanaa maxaa yeelay way fududahay in la dabaco.

Isha ku hay inaad hubiso in dhammaan qaybaha mashiinka ay si wanaagsan u shaqeeyaan ama aysan ahayn, Marka mashiinka loo yaqaan 'durdurka' Wadada Granulayetor-ka Roweelator 'uu shaqeynayo.

Waa inaad ku joojisaa mashiinka waqtiga, Haddii aad hesho heerkulka saliidda ee kordha ayaa kor loo qaaday. Kadib hubi oo tirtir, Sidoo kale geeska.

Saliida qaybahan si joogto ah si loo hubiyo in mashiinku sifiican u shaqeeyo.

- Sigaar udhac subagga qallalan.

- Ku tirtir subagga qallalan dusha sare ee suunka duuban 7 days.

- Add gearwheel oil before the speed reducer works.

- change the gearwheel oil every 4 months.

You should stop to check the machine immediately and eliminate it if the rotating gearwheel have acoustical shock.