Uus orgaaniline väetise granulaator on spetsiaalselt loodud orgaanilise väetise valmistamiseks. See võtab vastu niiske granuleerimismeetodi ja rikub ka traditsioonilisi granuleerimismeetodeid. Võite otse kääritatud tooraine granuleerida. Shunxinil on ka palju kääritusseadmed Käärimise aitamise eest, nagu Groove tüüpi kompost Turner, Roomarühma kompost Turner, kääritusmahutid ja nii edasi. Veelgi enam, Enne granuleerimist ei pea te tooraineid purustama ega kuivatama. See võib tuua teile rohkem tõhusust kui teised granulaatorid, sealhulgas pöörlevad granulaatorid, pannigraanundaja ja topeltrull pressigraalija. Kui vajate oma orgaanilise väetise tootmiseks tõhusat granuleerimismasinat, See masin suudab teie vajadustele vastata.

New organic fertilizer dedicated granulator for sale

Mudel: SXJZ-600(saab kohandada)

Installation Angle: 2°-2.5°

Moisture of Feeding Materials: 20%-40%

Size of Feeding Materials: 50 võrgusilm

Mõõtmed(mm): 4100×1600×1150

Võimsus(t/h): 1-1.5

Why Shunxin new organic fertilizers granulators is more efficient than other machines?

This granulating facility is designed with advanced technology and for making organic fertilizer. It has many advantages than other fertilizer making machine.

- The pellets made by are rich in organic matters. This organic fertilizer making machine is designed for making organic fertilizer. The organic content of finished pellets can reach 100%. You can get purer organic matter fertilizers.

- It can make high quality pellets. You can get high granulation rate as high as 90%, and the finished pellets have higher strength than the pellets which are made by disc pan granulator and rotary drum granulators.

- It can save your power consumption. Its power consumption for granulating are less than traditional organic fertilizer granulating machine. It can granulate fermented organic materials without drying in advance, which can save your usage of coal. Because of this, you can save more electricity in organic fertilizer production line.

- It can bring you high economic efficiency. This organic fertilizer granulator machine not only saves power consumption, but also reduces the labour force consumption. You don’t have to arrange worker to operate it when granulating in a fertiliser production line. Because it can granulate automatically. These decrease your costs. Samal ajal, you can get more economic efficiency because of its high production and high quality.

- It doesn’t need binder. The organic materials can grow-up inlaid because of the molecular interaction. So, you don’t need to add binder to materials.

Efficient organic fertilizer dedicated granulator machine for sale

Mudel: SXJZ-600(saab kohandada)

Installation Angle: 2°-2.5°

Moisture of Feeding Materials: 20%-40%

Size of Feeding Materials: 50 võrgusilm

Mõõtmed(mm): 4100×1600×1150

Võimsus(t/h): 1-1.5

How can you make fertilizer by using new organic fertilizer granulator?

This organic fertilizer granulator machine has speed promise functions and it uses high speed rotating mechanical stirring force and aerodynamic force to granulate. Here are 4 stages to operate it:

- You should feed the fermented materials into the inlet uniformly.

- You can control the pellets diameters by adjusting the materials mixing capacity and the speed. Üldiselt öeldes, the lower the mixing capacity, the higher the speed, the smaller the pellets.

- The inner structure of the machine will granulate materials by the high-speed stirring.

- Through the mixing, granulating, squeezing and polishing in the cylinder, the materials will be finished pellets and out from the outlet.

Organic fertilizer granular making machine for sale

Mudel: SXJZ-800(saab kohandada)

Installation Angle: 2°-2.5°

Moisture of Feeding Materials: 20%-40%

Size of Feeding Materials: 50 võrgusilm

Mõõtmed(mm): 4250×1850×1300

Võimsus(t/h): 1.5-2.5

What types of fertilizers can you make by Shunxin new organic fertilizers granulator?

New organic fertiliser dedicated granulator is used for producing organic fertilizers, and you can make organic fertilizers with organic wastes such as peat, sludge, chicken dung, livestock manure, coal ash, coal slime, sugar mill sludge, paper sludge, wine waste, straw, bean dregs, peat, jne. Different raw materials can make different fertilisers, you can choose raw materials according to the fertilizer you want to make. There are some tips of raw materials selecting:

- If you want to make bio organic fertilizers, you can granulate with peat, lignite, organic fertilizer sludge and straw.

- If you have much animal manure such as chicken manure, pig manure or cow dung, you can use them to make organic fertilizer by this machine.

- You can also produce complete feed and compound feed stuff with corn, beans , grass powder and so on.

- It is also applicable for producing cake fertilizer. You can use soybean cake as the main raw materials.

New wet granulator for organic fertilizer pellet making for sale

Mudel: SXJZ-800(saab kohandada)

Installation Angle: 2°-2.5°

Moisture of Feeding Materials: 20%-40%

Size of Feeding Materials: 50 võrgusilm

Mõõtmed(mm): 4250×1850×1300

Võimsus(t/h): 1.5-2.5

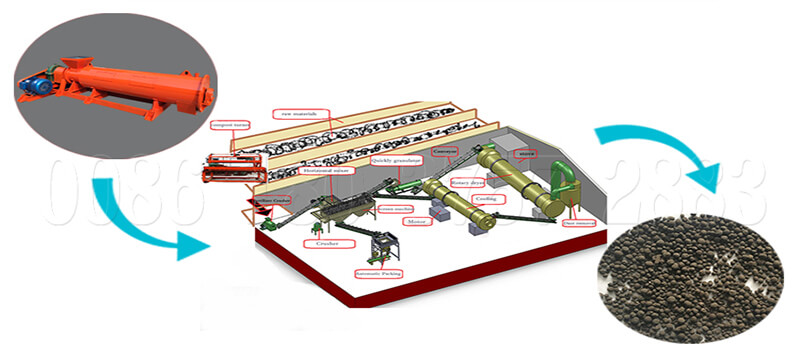

How does an organic fertilizer dedicated granulator production line make granules?

As we know, Seda patendiväetise granulaatorit kasutatakse peamiselt orgaaniliste väetise graanulite valmistamiseks. Kui, Kas teate, kuidas seda masinat kasutada orgaaniliste väetiste graanulite valmistamiseks tootmisliini moodustamiseks? Sellest voolavast diagrammist saate selle kohta rohkem üksikasju.

Pange kääritatud orgaaniline väetis punkrisse. Läbi vöökonveieri, Materjalid sisenevad purustusmasin ja siis segades. Pärast neid protsesse, On aeg granuleerida. Siiski, Märg granuleerimistehnoloogia tõttu kasutage uus orgaaniline väetise granuleerimismasin, Teil on vaja kasutada kuivatamine ja jahutusmasin paremate graanulite valmistamiseks. Kui soovite teha ühtseid graanuleid, Võite kasutada a ekraan Sõelumiseks ja seejärel kvalifitseerimata graanulitega väetis korrigeeritakse ja graanuleeritakse uuesti. Lõpuks, See on pakkimisaeg. Teie teabe saamiseks, Kui teil on muid nõudeid, Saame ka teie jaoks kohandada.

Millised on uute orgaaniliste väetiste granulaatori materjalide taotlused?

Erinevate väetiste tootmiseks saab kasutada palju orgaanilisi materjale. Paremate väetisegraanulite valmistamiseks, Materjalid peavad vastama uut tüüpi orgaaniliste väetiste granulaatori materjalide taotlustele.

- Toorainete niiskusesisaldus peaks olema vahemikus 25%~ 35%.

- Materjalid tuleks kääritada. Kui vajate, saate meie kääritatud kompostiseadmetega toorainet käärida.

- Parem kasutaksite toorainet, mis on läbi 50 võrgusilm.

Müüa orgaaniline väetisegraanulite valmistamise masin

Mudel: SXJZ-1200(saab kohandada)

Installation Angle: 2°-2.5°

Moisture of Feeding Materials: 20%-40%

Size of Feeding Materials: 50 võrgusilm

Mõõtmed(mm): 4900× 2550 × 1800

Võimsus(t/h): 4-6

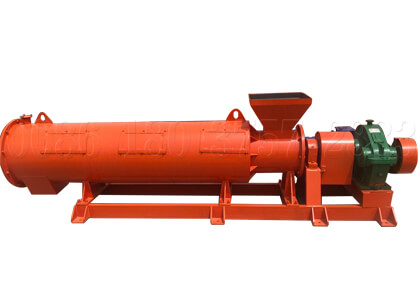

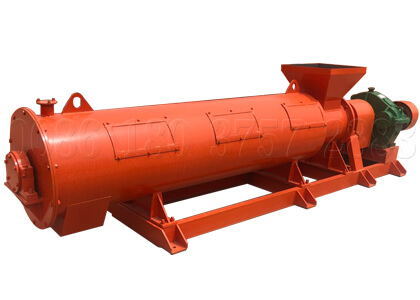

Uute orgaaniliste väetiste granulaatori struktuuri üksikasjad

This new designed organic fertilizer making equipment employs advanced design, whether on the structure or the parts materials.

- It mainly includes 5 parts: Motor, reducer, rotor, cylinder and body frame. We use high quality motor which reaches national standards. And the motor can provide machine strong power. Siiski, it won’t cost you too much electricity.

- The reducer employs special materials to make the machine run stable. The rotor includes 3 parts: Shaft, stirring gear, and stirring gear head. Both of the shaft and stirring gear use special materials which are sturdy and wearable. Veelgi enam, the length of stirring gear is adjustable. As for the stirring gear head, we also use alloy steel cutter head to make it work better.

- Both of the cylinder and body frame use thickened seamless steel tube which make them durable and not easy to deform. These materials we use are high quality.

If you want higher configuration or you have other requirements for the machine, Shunxin can also provide customized service for you. Contact our customer service center, we will try our best to meet your needs.

New organic manure fertilizer pelletizer for sale

Mudel: SXJZ-1200(saab kohandada)

Installation Angle: 2°-2.5°

Moisture of Feeding Materials: 20%-40%

Size of Feeding Materials: 50 võrgusilm

Mõõtmed(mm): 4900× 2550 × 1800

Võimsus(t/h): 4-6

Want to make granular fertilizer efficiently with your new graunlator, do the following 2 steps

Before you take a production, you had better take a test on machine. Taking a test on machine will let you know what you should do to make high quality pellets. Nende sammude järgimine, you will get a more efficient production.

- Adjust the moisture content of raw materials. This new type dedicated organic fertilizer granulator machine is a wet granulation machine, so you should adjust the moisture content raw materials reasonably to make granules better. You can use moisture measuring instrument to measure the moisture content. And then you’d better adjust the moisture content of raw materials to 25%~35%.

- Taking a pilot production. You can use low moisture content raw materials for a pilot production, and then adjusting the moisture content according to the effect of finished pellets. As a rule, if the finished pellets are too big, you can decrease the moisture content of raw materials. If there are small pellet and even powder, you should increase the moisture content.

Granulation effects of our new designed organic fertilizer granulation machine

SXJZ-600 patent organic fertilizer dedicated granulator production line delivering to Korea

This is an organic fertilizer production line, which uses our patent fertilzier granulator for pelletizing. It is suiatble for your small scale organic fertilizer production plant. Our Korean customer utilizes it for recycling animal waste to available organic fertilizers for its 1 ton per hour fertilizer production business.

For the 1 ton per hour production requirements, we recommed our small scale new organic fertilizer production machines. The whole fertilizer production line includes our small windrow turner machine, semi-wet crusher, horizontal mixer, drying and cooling machine, rotating screener ja automatic fertilizer packing machine.

Questions & answers for our new organic fertilizer dedicated granulation machine

The patent organic fertilizer granulator is designed for making organic fertilizers pellets. There are some questions asked by our customers about our organic fertilizer pellet mill.

Question: How long is your organic fertilizer granulator’s lifetime?

Asked by our South Korean customer

Answer: Üldiselt, our patent organic fertilizer granulation machine’s lifetime is about 8 to 10 years. We utilize thickened seamless steel tube for its cylinder and body frame. And the stirring teeth are durable. These specialized designs make sure that our organic fertilizer dedicated granulating equipment can work for a long time. Veelgi enam, if you can do some routine maintenance, it can prolong the service lifetime of granulator.

Sam Song, professional granulator engineer

Question: Compared to other pelletizers (ring die pellet machine, for example), is your company’s stirring type organic fertilizer Granulator hard enough?

An organic fertilizer manufacturer in Indonesia

Answer: Yeah, our stirring type granulation can make pellets, which is hard enough for transporting and storing. Vahepeal, these pellets are also good for soil decomposing and absorbing. Siiski, if you use ring die pellet machine for pelletizing organic fertilizers, the fertilizer granular will be too hard to soil decompose and absorb. Usually, selle ring die type is mainly used for crude fiber granulating. Kui, this stirring granulator is designed for making organic fertilizer pellets. Seega, for your organic fertilizer granular manufacturing, our organic fertilizer pellet making machine will be a better choice than ring die type.

Frank Liu,

Question: What sizes of materials should I prepare for your patent organic fertilizer granulator? Is 10 mesh OK?

A cow farm owner from Yemen

Answer: For this new organic fertilizer granulator machine, the materials size about 50-200 võrgusilm is the best.

10 mesh is OK if you only use it for testing. Siiski, for your mass fertilizer production, it will be better for you to make your 10 mesh materials into finer powders. And then the granulation effects will be better.

There are many types of fertilizer crushing machines for your reference in Shunxin. They can help you make fine powder, which is suitable for granulating requirements. Selle masinaga, the granulated organic fertilizers will be better in quality. Our smallest vertical crusher SXFLF-600 will be suitable for you. Vahepeal, we can provide you EXW price.

Jenny Cao